The Atlas Copco E-Air H185 VSD is a single-stage, oil-injected, rotary screw type air compressor, powered by an Atlas Copco electric motor with Class H insulation powering up to 7150 rpm. The E-Air VSD compressor is a game changer when it comes to performances, energy-efficiency and versatility.

The unit hosts the new generation C80 Screw element in its air end combined with an Atlas Copco integrated permanent magnet motor, cooling circuit, air/oil separation and control systems.

Special attention has been given to the overall product quality, user friendliness, ease of serviceability, and economical operation to ensure best in class cost of ownership.

The Unique feature of this new range is the PACE functionality coupled with the intuitive XC2003 controller. This pioneering technology enables multiple pressure and flow settings, ensuring you match air flow and pressure to your application needs.

Displayed while running

- Hours

- Outlet pressure

• Operational Buttons

- Start and stop of the unit

- View measurements, settings and alarms

- Multi position cursor to navigate menus

• Compressor measurements displayed

- Running hours

- Clock

- Regulating pressure

- Emergency stop count

- Average fuel consumption

- Minor and major service counters in hours and

days

• Warnings and Shutdowns

- Power phase detection

- Main Motor Overload

- Fan Motor Overload

- Vessel pressure

- Pressure Air Discharge

- Element Temperature

• Alarms

- View current & historical alarms present

- History of last 20 alarms and events with time

and date stamps

• Settings

- Reset service timers

- Language settings

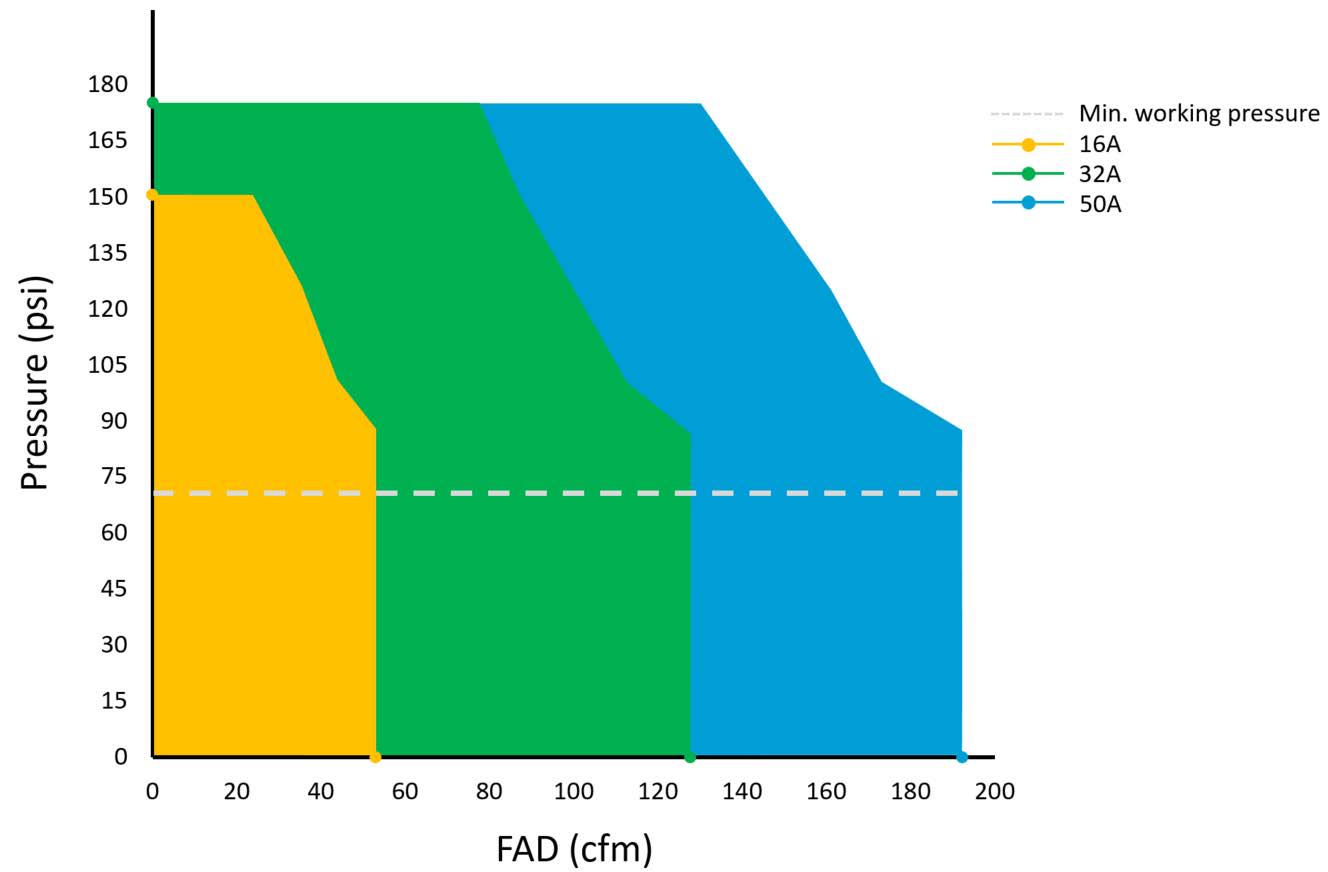

| Model | 50A | 32A | 16A | |

| Minimum effective receiver pressure | psi(g) | 72.5 | 72.5 | 72.5 |

| Maximum effective receiver pressure (Unloaded) | psi(g) | 174 | 174 | 152 |

| Free air delivery | ||||

| at pressure setting 174 psi | cfm | 130.3 | 77.1 | NA |

| at pressure setting 150 psi | cfm | 143.4 | 85.8 | 22.9 |

| at pressure setting 125 psi | cfm | 160.4 | 99.6 | 34.5 |

| at pressure setting of 100 psi | cfm | 172.5 | 112.1 | 43.0 |

| at pressure setting of 87 psi | cfm | 191.5 | 126.9 | 52.1 |

| Max. sound pressure level (Lp @ ISO 2151) | dB(A) | 65 | 63 | 61 |

| Compressed air temperature at outlet valve with aftercooler | °C (°F) | 54 (129) | 54 (129) | 54 (129) |

| Max. ambient temperature at sea level | °C (°F) | 50 (122) | 50 (122) | 50 (122) |

| Max. ambient temperature at sea level with aftercooler | °C (°F) | 45 (113) | 45 (113) | 45 (113) |

| Min. starting temperature with cold weather equipment | °C (°F) | -20 (-4) | -20 (-4) | -20 (-4) |

| Min. starting temperature without cold weather equipment | °C (°F) | -10 (-14) | -10 (-14) | -10 (-14) |

| Max. oil content of compressed air (w/o UD Filter) | mg/m3 | 8 | 8 | 8 |

| Number of compression stages | 1 | 1 | 1 | |

| Capacity of compressor oil system | US Gal (l) | 4.4 (17) | 4.4 (17) | 4.4 (17) |

| Net capacity of air receiver | US Gal (l) | 9.25 (35) | 9.25 (35) | 9.25 (35) |

| Air volume at inlet grating (approx.) | ft3/s | 46.97 | 46.97 | 46.97 |

| Motor | Atlas Copco |

Atlas Copco | Atlas Copco | |

| Installed motor power | hp (kW) | 35 (26) | 35 (26) | 35 (26) |

| Voltage | V | 380-460 (+/- 10%) | 380-460 (+/- 10%) | 380-460 (+/- 10%) |

| Current | A | 50 | 50 | 50 |

| Fan(s) electrical power input | hp (kW) | 1.25 (0.92) | 1.25 (0.92) | 1.25 (0.92) |

| Frequency | Hz | 60 | 60 | 60 |

| Number of phases | 3 | 3 | 3 | |

| Service Factor | 1.25 | 1.25 | 1.25 |

Atlas Copco's small electric air compressors are indispensable on any job site where you have access to clean power. For everyday tools such as impact wrenches and pile drivers as well as nails guns and sanders, a powerful force is essential.

A compressor like this can be utilized both for larger remodel installations as well as smaller home framing projects. The smaller electric units are ideal compressor if you have access to clean power, working residential jobs, high-rise construction or places where noise is a concern.

An air compressor can effectively clean out your irrigation system of standing water at the end of each warm season. Before you shut the system off for the fall and winter, pressurized air can offer the power needed to push out all water along each run and spout of your sprinkling system..