The PAS 100 HFS Atlas Copco pump is designed to withstand toughest applications and delivers best in class pumping efficiency. One of the most common area of utilization is the Construction dewatering and municipal market segment where reliability, serviceability and versatility is the key to provide a customized solution. Other suitable applications can be found within the Industry, Mining or Oil & Gas segment. Atlas Copco pumps are packed with features that not only meet, but exceed the needs of our customers..

| Pump | |

|---|---|

| Model | PAS 100HFS T4F |

| Qmax | 1230 USgpm |

| Hmax | 164 ft |

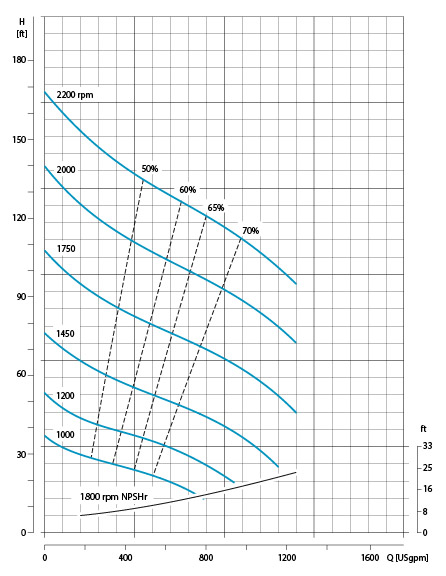

| Q max eff. | 1000 USgpm |

| Eff. max | 70% |

| Suction port | 4" Flange - 150# ANSI |

| Delivery port | 4" Flange - 150# ANS |

| Impeller type | Semi-open, 2 vane |

| Impeller diameter | 10" |

| Solids handling | 3" |

| Material | |

| Casing | EN-GJL-200 cast iron |

| Impeller | EN-GJS-500 ductile iron |

| Wear Plate | EN-GJL-200 cast iron |

| Shaft | 39NiCrMo4 steel |

| Mechanical Seal faces | Tungsten carbide / Tungsten carbide |

| Elastomers | VITON |

| Check Valve | ASTM A536 ductile iron + NBR rubber flap |

| Separator | EN AC-42100 ( AlSi7Mg0.3) - Aluminum |

| Priming System | |

| Vacuum pump | |

| Vacuum pump type | Diaphragm |

| Nominal air capacity | 29.6 cfm |

| Max vacuum | - 26.6 inHg |

| Drives | Link belt |

| Engine | |

|---|---|

| Make | Kohler |

| Model | KDI 1903TCR |

| Type | Diesel turbo common rail |

| Displacement | 1.9 Liter (114in³) |

| No. cylinders | 3 |

| Cooling | Liquid with radiator |

| Rpm type | Variable |

| Max operating speed | 2.200 rpm |

| US emissions | EPA Tier 4F |

| Starting | Electric |

| Engine system voltage | 12 V |

| Engine Power rating | 49 HP |

| Control panel | |

| Model | PW 750 |

| Manual operation | |

| Automatic operation: start-stop with transducers or floats | |

| FleetLink Optional | |

| Arrangement | |

| Technical data | |

| Material | ASTM A36 steel |

| Coatings | Polyester powder, average thickness of 3 MIL |

| Features | Lifting beam, PE-Fuel tank and Fender |

| Battery | Acid charge Pb-Ca maintenance free, 12 V - 1150 CCA |

| Fuel tank capacity | 30 USG Net Volume |

| Fuel consumption | 1.8 US Gal/hr @2200 rpm @BEP |

| Dry weight | 2735 lbs |

| Wet weight | 2990 lbs |

| Speed | Impeller Dia. | Style | Solids Dia. | Ns | Suction | Discharge | No. Vanes |

| Various | 10" / 250 mm | Semi-Open | 3" / 76 mm | 2200 rpm | 4" / 100 mm | 4" / 100 mm | 2 |

| Efficiency |

Solids handling |

Easy maintenance |

Polyethylene Fuel tank |

| The 10" impeller with 70% efficiency at B.E.P. provides best pumping result with minimal efforts | Semi-open impeller type with solids handling capability of 3" for trouble free operation | Hinged cover for direct access to the impeller and pump volute | Corrosion-free PE tank provides longer lifetime and avoids tank cleaning due to oxidation |

Bypass pumping involves maneuvering liquid (sewage, trash, water, etc.) around a damaged pipe without interrupting the flow of liquid while the repairs are underway. This process is critical for many rehab projects, as it allows for a pipe to be repaired or replaced without spillage on public or private property. Bypass pumping uses a PAS HF, which is a centrifugal pump that can handle liquids containing solids of up to 1.8". Because of this, the PAS HF pump is well suited for bypassing in construction, industrial, and municipal applications.

Bypass is common in these sectors:

Solids can build up at wastewater treatment plants or places a digestor is used over time as they settle out with solids. The build-up of solids, sludge, and stringy material in digester tanks can negatively impact the operation of digesters. This requires the right pump, usually with an open impeller to get a clean, easily flowing body of water.

Areas for Digestor cleanouts :

Site dewatering is the process of taking and removing water from construction sites, quarries, mine shafts, or any other area. Extracting water from these areas is crucial to maintain a safe working environment as well as reduce any costly delays.

Due to the PAS' ability to handle pumping high volumes, this pump is able to displace not only water, but sewage, industrial waste, chemicals, and even some solid products.

Areas for site dewatering :