Why use our air compressors in your brewery?

Certified clean air

We have set the standard concerning uncontaminated air. Being the first compressor manufacturer to be ISO 22000 certified and the first to have been certified by a third party on ISO 8573-1 (2010) Class 0 clean air.

This gives breweries peace of mind that the air is as pure as possible. Highly trained employees manufacture compressors in a safe and controlled environment.

Solutions for every step of the brewing process

Doesn’t matter if you are a large brewery, microbrewery or a craft brewery, our compressors offer solutions for every single size, because compressed air is used in nearly every step of any brewery’s production process. From fermentation and aeration to bottling and carbonating, we can tailor our products specifically to the brewery’s needs depending on their energy, size and noise requirements.

Optimal cost of total ownership

Being the most reliable machine on the market comes with additional benefits. Having an oil-free air compressor means you do not have to replace expensive filters, there are no extra energy costs for pressure loss due to these filters. This brings down maintenance costs.

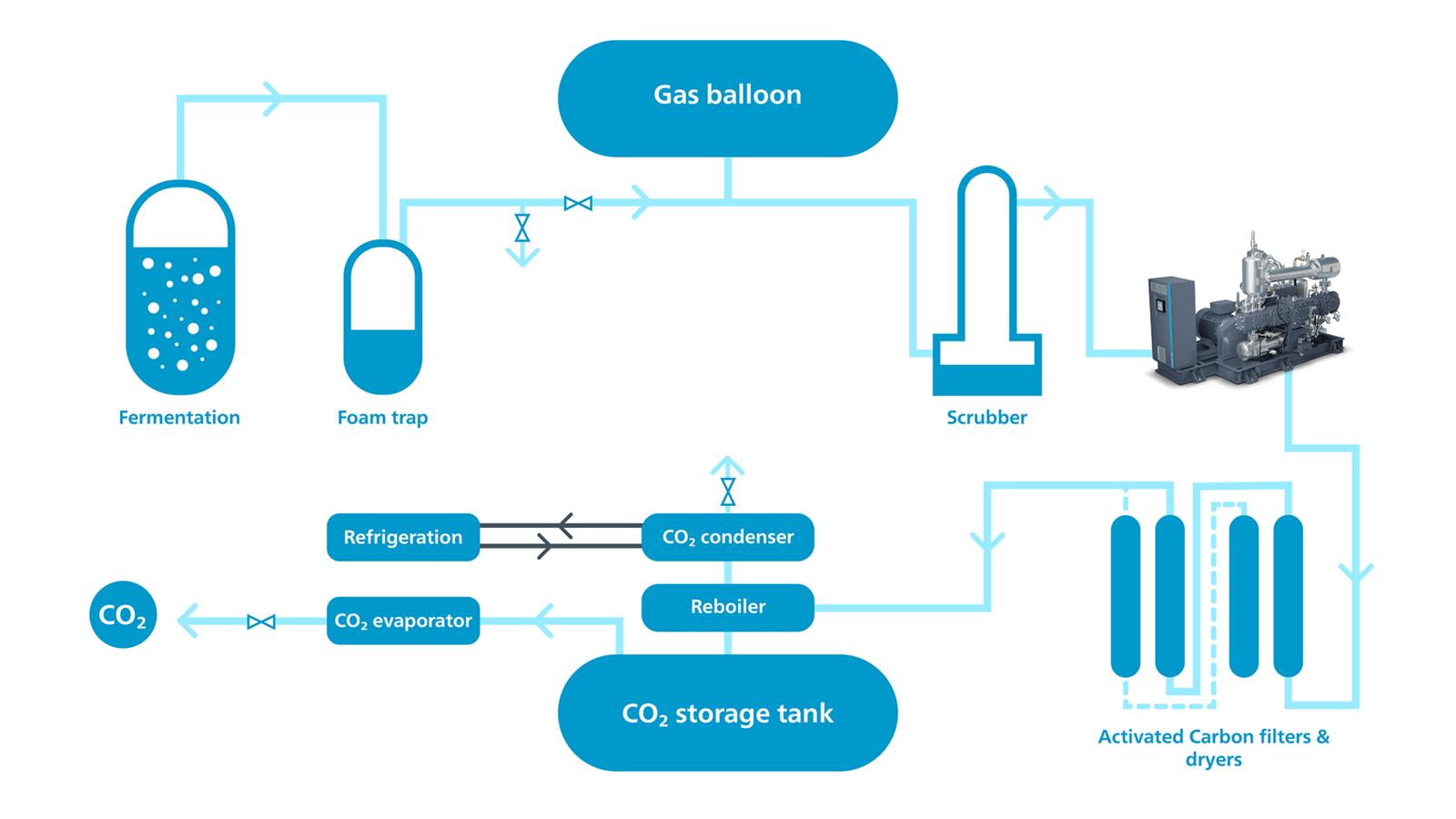

Additionally, it is possible to recover the CO2 that is created during the fermentation process for commercial ends or self-use. Finally, thanks to our global service network that contains more than 180 countries downtimes are solved in no-time, no matter where you are or at what time.

Applications

Oil-free compressed air is used for cleaning bottles and packaging prior to the filling.

If the air is contaminated it can alter the flavor, odor and foam besides being a health hazard.

Oil-free compressed air is used for cleaning bottles and packaging prior to the filling.

If the air is contaminated it can alter the flavor, odor and foam besides being a health hazard.

Compressed air is used to control the valves and actuators in automated lines for packaging, labelling and more.

Oil-free air prevents automated components from jamming, thereby lowering maintenance costs.

Compressed air is used to control the valves and actuators in automated lines for packaging, labelling and more.

Oil-free air prevents automated components from jamming, thereby lowering maintenance costs.

Compressed air supplies oxygen to bacteria during the fermentation process (aeration). This converts carbon hydrates to alcohol using micro-organisms.

Important during the process is delivering the exact amount of compressed air and maintaining the correct oxygen level in order to determine the quality of the yeast.

Compressed air supplies oxygen to bacteria during the fermentation process (aeration). This converts carbon hydrates to alcohol using micro-organisms.

Important during the process is delivering the exact amount of compressed air and maintaining the correct oxygen level in order to determine the quality of the yeast.

It doesn’t matter if you're a large brewery, microbrewery or a craft brewery; our compressors offer solutions for every single size, as compressed air is used in nearly every step of any brewery’s production process. From fermentation and aeration to bottling and carbonating, we can tailor our products specifically to the brewery’s needs depending on their energy, size and noise requirements.

Being the most reliable machine on the market comes with additional benefits. If you choose an oil-free air compressor, it means you do not have to replace expensive filters & there are no extra energy costs for pressure loss due to these filters. This brings down maintenance costs. Additionally, it is possible to recover the CO2 that is created during the fermentation process for commercial ends or self-use. Finally, thanks to our global service network that contains more than 180 countries downtimes are solved in no-time, no matter where you are or at what time.

Worried about the reported national CO2 shortage? We've bundled together five of our most popular air and nitrogen offerings into convenient packages to facilitate easier ordering and financing. Read the details here!

CO2 or Nitrogen for Your Brewery?

CO2 is essential for carbonization, but did you know you can replace CO2 with nitrogen for inerting, purging, and bottling? This can reduce your CO2 bill by around 70% and provide an instant payback that goes straight to the bottom line. It’s also great for the environment and you can reduce CO2 emissions by dozens of metric tons annually. The other good news? If you own a compressor, you’re already 50% of the way towards generating your own nitrogen!

Other fun facts include:

- Did you know that a barrel of beer can take 8 Lbs. CO2 to produce?

- Switching to nitrogen (for everything except carbonization) can reduce your costs by up to 70%!

- A brewery producing 10,000 barrels a year can reduce their CO2 emissions by 24 metric tons.

We can provide all the nitrogen you will ever need for under $500 per month - with no up-front costs (subject to required volume and eligibility). Don't take our word for it. Watch the math in action!

CO2 Recovery

If you’re a large brewery, producing several hundred-thousand barrels of beer a year, then you know how much CO2 you produce! Have you looked at a CO2 recovery system? Do you already have one, but find ongoing maintenance a hassle? Could you use the recovered CO2 in your operations or even sell it to help profits? If the answer was yes to any of these questions, then the newly developed Atlas Copco CO2 recovery system could be right for you.

Process Chillers

- Every brewer understands the Importance of maintaining temperature control during the entire process. At times you need extreme heat but once that heat has fulfilled its job you need to cool the water down very quickly – that’s where Atlas Copco’s chiller range comes into play

- Plug-n-play connections for immediate installation.

- Optimization of space and ambient conditions with the option to install indoors and outdoors.

- Full control of your process with various monitors and safety devices combined into a central controller.

- Microchannel condensers design allows for 30% less refrigerant charge compared to others.

Process Filtration

- Atlas Copco’s range of filtration products were designed with the brewing industry in mind. The technology is advanced, but the goal is simple – removing microorganisms which should not be there and ensuring the best end-product. The range includes cartridges, housings, and bags that cover the needs of any brewery, big or small.

- Absolute filtration at an efficiency of 99.9% down to a 0.01 micron rating.

- Sterilizing grade (membrane) filter cartridges with up 8000-hour service life.

- Integrity testable membrane filters to ensure product quality.

Download Our Air, Gas, and Financing Guides for Brewers!

- Atlas Copco Brewery Industry Brochure 8.9 MB, PDF

See How Our Equipment is Used By Our Brewery Customers!

Olde Mecklenburg Brewery uses oil-free air in brewing process

The Olde Mecklenburg Brewery in Charlotte, North Carolina (USA) uses oil free air compressors from Atlas Copco in their brewing processes to guarantee that their air is clean, their nitrogen is pure and their beer is always uncompromised.

Barranco Beer Company brews class 0 beer

Barranco Beer Company in Peru uses oil-free air compressors provided by Atlas Copco to produce high quality class 0 beer.

Packaging/Labeling

Ebook: Compressed air and nitrogen for microbreweries

In this microbrewery ebook, read all about:

- the process of beer brewing

- the role of compressed air in beer brewing

- the role of Nitrogen in beer brewing

- the key compressed air and nitrogen requirements in microbreweries

- the design of a compressed air and nitrogen system

- the importance of monitoring and maintenance