The Atlas Copco E-Air V1100 VSD is a single-stage, oil-injected, rotary screw type air compressor, powered by a Danfoss electric motor with Class F insulation The E-Air VSD compressor is a game changer when it comes to performance, energy-efficiency and versatility.

The unit hosts the new generation Screw element in its air end combined with a Danfoss integrated permanent magnet motor, cooling circuit, air/oil separation and control systems.

Special attention has been given to the overall product quality, user friendliness, ease of serviceability, and economical operation, to ensure best in class cost of ownership.

The unique feature of this new range is the PACE functionality coupled with the intuitive XC4004 controller. This pioneering technology enables multiple pressure and flow settings, ensuring you match air flow and pressure to your application needs.

Standard instrument package includes an operating pressure gauge, and fully diagnostic ECU controller with large display. The intuitive Atlas Copco XC4004 controller is easy to operate with all functions conveniently at your fingertips. The controller also manages the motor operating system, and a number of safety warnings and shut downs on various parameters (listed below).

Easy to use interface

• 7 inch anti-glare LED screen.

• Simultaneous view of pressure and flow increase control on the output flow required by your application.

• Personalized interaction through metrics and language settings.

Powerful insights increase uptime

• Easy access to trends of 15 parameters.

• Increase uptime through preventative maintenance

Save time through remote controlling

• Mirror application: control feed air compressor through second controller at point of use.

• All machine parameters remotely adjustable: ECOmode, Dynamic Flow Boost, multi pressure / flow settings, emergency stop...

• Hard wired or RRC (radio remote connection)

| Model | E-Air V1100 VSD | |

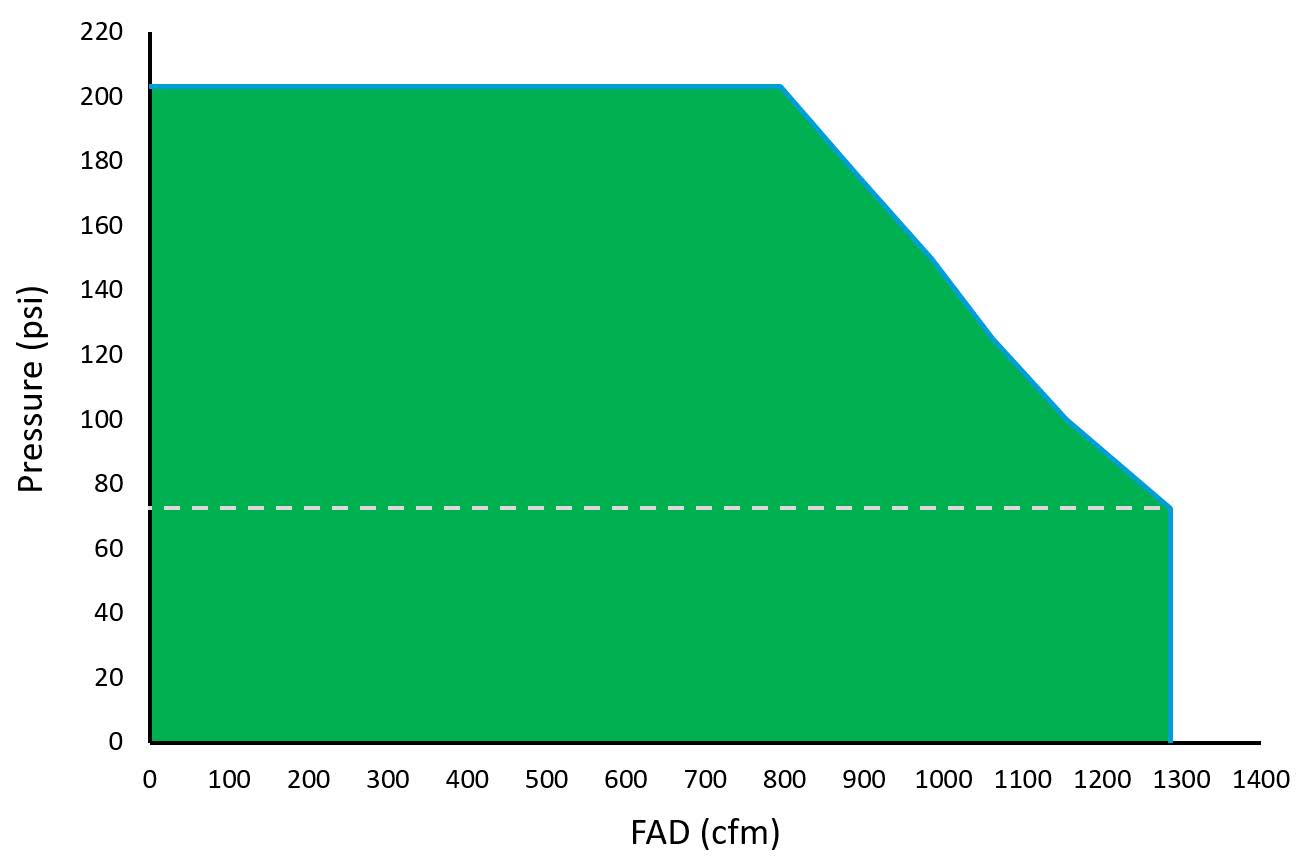

| Minimum effective receiver pressure | psi(g) | 72.5 |

| Maximum effective receiver pressure (Unloaded) | psi(g) | 203 |

| Free air delivery | ||

| at pressure setting 203 psi | cfm | 794.6 |

| at pressure setting 175 psi | cfm | 894.2 |

| at pressure setting 150 psi | cfm | 985.3 |

| at pressure setting of 125 psi | cfm | 1061.6 |

| at pressure setting of 100 psi | cfm | 1154.8 |

| at pressure setting of 72.5 psi | cfm | 1286.2 |

| Max. sound pressure level (Lp @ ISO 2151) | dB(A) | 72 |

| Compressed air temperature at outlet valve with aftercooler | °C (°F) | Amb. +15°C (Amb. +59°F) |

| Max. ambient temperature at sea level | °C (°F) | 50 (122) |

| Max. ambient temperature at sea level with aftercooler | °C (°F) | 45 (113) |

| Min. starting temperature with cold weather equipment | °C (°F) | -25 (-13) |

| Min. starting temperature without cold weather equipment | °C (°F) | <-25 (<-13) |

| Max. oil content of compressed air (w/o UD Filter) | mg/m3 | 2.7 |

| Number of compression stages | 1 | |

| Capacity of compressor oil system | US Gal (l) | 19 (72) |

| Net capacity of air receiver | US Gal (l) | 47.55 (180) |

| Air volume at inlet grating (approx.) | ft3/s | 406.1 |

| Motor |

|

|

| Installed motor power | hp (kW) | 280 (208) |

| Voltage | V | 380-460 (+/- 10%) |

| Current | A | 350 |

| Fan(s) electrical power input | hp (kW) | 10 (7.5) |

| Frequency | Hz | 50-60 |

| Number of phases | 3 |