The E-AIR T900 have been designed to offer true versatility through compact dimensions and useful and intuitive electronic controller. Providing exceptional reliability and efficiency, these units are designed to operate in a wide range of applications in the harshest of work environments.

Whether being used for running pneumatic breakers, general construction work, sandblasting or for rental are all within the capability of these units. Wide choices of options are available which to build these units specific from the simplest to most complex specialized application.

Despite the overall compactness these compressors still provide exceptional access to all the service and maintenance points. The compressor is driven by the latest WEG high efficient motor ensuring low operational costs and high resale value.

Above all Atlas Copco compressors are build for reliability, easily maintained, CE and CSA/UL compliant, providing many years of trouble free performance

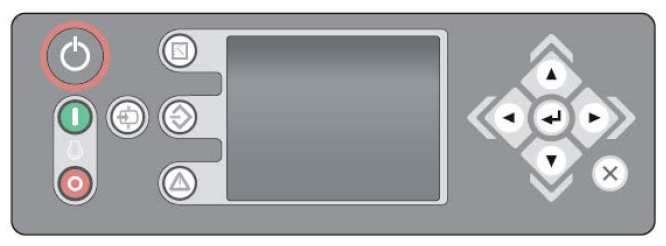

Displayed while running

- Hours

- Outlet pressure

• Operational Buttons

- Start and stop of the unit

- View measurements, settings and alarms

- Multi position cursor to navigate menus

• Compressor measurements displayed

- Running hours

- Clock

- Regulating pressure

- Emergency stop count

- Average fuel consumption

- Minor and major service counters in hours and

days

• Warnings and Shutdowns

- Power phase detection

- Main Motor Overload

- Fan Motor Overload

- Vessel pressure

- Pressure Air Discharge

- Element Temperature

• Alarms

- View current & historical alarms present

- History of last 20 alarms and events with time

and date stamps

• Settings

- Reset service timers

- Language settings

- Unit of measure changes

| Model | E-AIR T900 | E-AIR T900 | |

| Frequency | Hz | 60 | 50 |

| Minimum effective receiver pressure | PSI | 58 | 58 |

| Maximum effective receiver pressure | PSI | 150 | 150 |

| Maximum ambient temperature | °C (°F) | 45 (113) | 45 (113) |

| Minimum ambient temperature | °C (°F) | 0 (32) | 0 (32) |

| Motor shaft speed (rpm) | rpm | 1790 | 2890 |

| Free air delivery | |||

| Effective working pressure (bar(g)) 4 | CFM (l/s) | 903 (426) | 903 (426) |

| Effective working pressure (bar(g)) 5 | CFM (l/s) | 896 (423) | 896 (423) |

| Effective working pressure (bar(g)) 6 | CFM (l/s) | 896 (423) | 896 (423) |

| Effective working pressure (bar(g)) 7 | CFM (l/s) | 896 (423) | 896 (423) |

| Effective working pressure (bar(g)) 8 | CFM (l/s) | 884 (417) | 884 (417) |

| Effective working pressure (bar(g)) 9 | CFM (l/s) | 879 (415) | 879 (415) |

| Effective working pressure (bar(g)) 10 | CFM (l/s) | 875 (413) | 875 (413) |

| Effective working pressure (bar(g)) 10,4 | CFM (l/s) | 871 (411) | 871 (411) |

| Total electrical power input (kW) | |||

| Effective working pressure (bar(g)) 4 | kW (HP) | 151 (202) | 159 (213) |

| Effective working pressure (bar(g)) 5 | kW (HP) | 159 (213) | 162 (217) |

| Effective working pressure (bar(g)) 6 | kW (HP) | 161 (216) | 169 (226) |

| Effective working pressure (bar(g)) 7 | kW (HP) | 169 (227) | 178 (239) |

| Effective working pressure (bar(g)) 8 | kW (HP) | 177 (237) |

186 (249) |

| Effective working pressure (bar(g)) 9 | kW (HP) | 185 (248) | 194 (260) |

| Effective working pressure (bar(g)) 10 | kW (HP) | 194 (260) | 204 (274) |

| Effective working pressure (bar(g)) 10,4 | kW (HP) | 195 (261) | 205 (275) |

| Unload | kW (HP) | 74 (99) | 74 (99) |

| Total electrical power input at unload | kW (HP) | 78 (105) | 79 (106) |

| Compressed air temperature at outlet valve | °C(°F) | Amb. +16°C +/- 7°C (Amb. +61°F +/- 45°F) | Amb. +16°C +/- 7°C (Amb. +61°F +/- 45°F) |

| Fan(s) shaft power | kW (HP) | 4 (5) | 4 (5) |

| Frequency | kW (HP) | 4 (5) | 5 (6.7) |

| DESIGN DATA | |||

| Drive motor installed power | kW | 9160 kW (220 HP-cv) | 160 kW (220 HP-cv) |

| Drive motor name | Motor 3Ph W22 WEG | Motor 3Ph W22 WEG | |

| Housing | 315S/M | 315S/M-02 | |

| Motor shaft speed | rpm | 1790 | 2980 |

| Voltage | 380/440/460/575 Volts | 400 Volts | |

| Current | A | 297/256/243/194 | 264 |

| Service Factor | 1,2 | 1,2 | |

| Ip/In | 8 | 8 | |

| I.P. | IPW55 | IPW55 | |

| Fan motor name | AT112S-4 | AT112S-4 | |

| Housing | 112M | 112M | |

| Motor shaft speed | rpm | 1740 | 1460 |

| Voltage | 220/380/440/460/575 | 400V | |

| Current | A | 14,2/8,24/7,11/6,6/ | 8,32 |

| Service Factor | 1 | 1,15 | |

| Ip/In | 7 | 8,2 | |

| I.P. | IP55 | IP55 | |

| Shipping mass – 50 Hz wet | Kg (Ib) | 3160 (6967) | |

| Shipping mass – 50 Hz net | Kg (Ib) | 3105 (6845) | |

| Shipping mass – 60 Hz wet | Kg (Ib) | 2963 (6532) | |

| Shipping mass – 60 Hz net | Kg (Ib) | 2908 (6411) | |

| Shipping mass – Option DDx/PDx filters | Kg (Ib) | 40 (88) | 40 (88) |

| Shipping mass – Weight Undercarriage | Kg (Ib) | 517 (1140) | 517 (1140) |