The Atlas Copco 400 Series CD T4F is single-stage, oil-injected, air compressors, powered by a liquid-cooled, four-cylinder turbocharged diesel engine.

The units consist of an air end, diesel engine with exhaust treatment, cooling circuit, air/oil separation and control systems - all enclosed within a sound dampened HardHat™ enclosure.

A range of undercarriage formats, factory and locally installed options are available.

Special attention has been given to the overall product quality, user friendliness, ease of serviceability, and economical operation to ensure best in class cost of ownership.

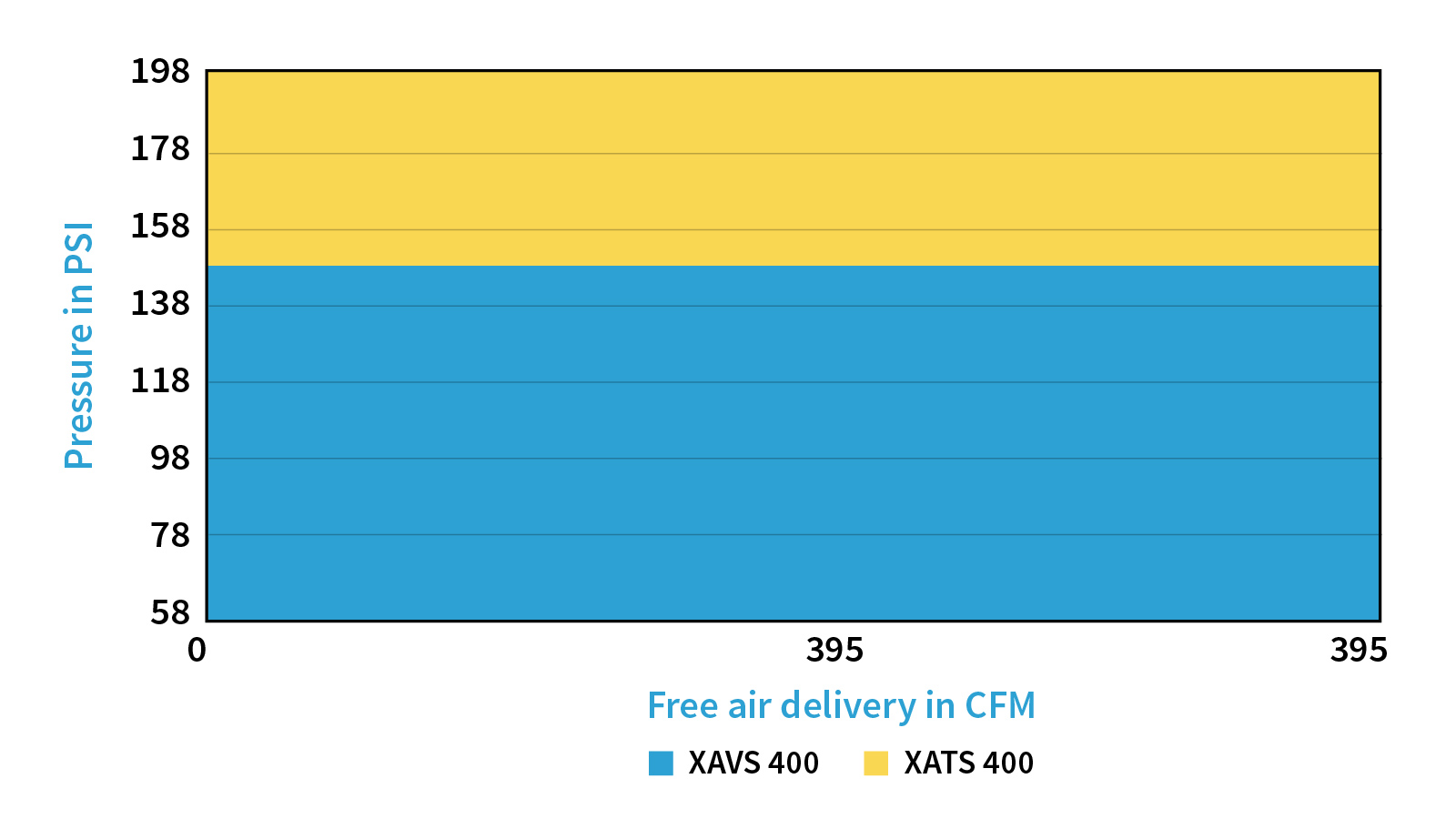

PRESSURE & FLOW

CONTROLLER

You need PACE... To win the RACE!

The skillfully versatile XA(T)S 400 range offers you two models with multiple possibilities. Thanks to its intuitive PACE system (Pressure Adjusted thru Cognitive Electronics) the new 400 cfm models give you the most options from a single compressor. The Xc2003 controller is the secret behind our “versatility range”. These compressors can work on various pressure settings, thanks to the built-in PACE technology. One compressor can power handheld tools at 100 psi, deliver 150 psi for sandblasting or 200 psi for cable blowing.

The Xc2003 also holds more parameters that help you get the most out of your compressor. Full diagnostics, insight into your compressor’s utilization and information about planned maintenance. It’s all there.

SPECIFICATIONS

| Working pressure | psi | 150 |

| Free air delivery | cfm | 395 |

| Max. unloading pressure | psi | 150 |

| Min. working pressure | psi | 58 |

| Air compressor outlets | 2 x ¾” & 1 x 1 ½“ | |

| Max. sound pressure level @ 23’ (7m) | dB(A) | 76 |

| Engine | ||

| Model | Caterpillar C4.4 | |

| Number of cylinders | 4 | |

| Emissions regulation | US EPA Tier | T4F |

| Output at rated speed (2400 rpm) | hp | 155 |

| Aspiration | Turbocharged | |

| Engine speed (unloaded) | rpm | 1500 |

| Engine speed (maximum loaded) | rpm | 2200 |

| Capacity and consumption | ||

| Fuel tank capacity | US gal (l) | 52 (197) |

| Fuel consumption @ 100% load | gal/hr (l/hr) | 6.8 (25.7) |

| DEF tank capacity | US gal (l) | 5.7 (21.7) |

| DEF consumption @ 100% load | gal/hr (l/hr ) | 0.30 (1.1) |

| Dimensions and weight | ||

| (trailer/Skid mounted) | ||

| Length | in | 161 / 113 |

| Width | in | 71.5 / 71.5 |

| Height | in | 70 / 65 |

| Weight (wet) | lbs | 4708 / 4616 |

Pneumatic Directional Boring

Pneumatic Directional boring refers to smaller-diameter bores over shorter distances while horizontal directional drilling, or HDD, indicates larger diameters and longer distances.

PDB and HDD are trenchless technologies that uses surface-launched equipment to drill underground horizontally and install pipes, conduits, and cables. they are used in several industries, such as utilities and telecommunications, at sites with limited space (e.g., dense, urban areas) or where traditional vertical excavations are too hazardous (e.g., under lakes and rivers).

- Can be employed to install underground utilities

- Allows operators to drill horizontally controlling the direction of drill

- The compressor powers the hammer at the end of the drill and uses air to clear dirt and debris