The Atlas Copco V21 Sd T4F is a silenced, two-stage, oil-injected screw type air compressor, powered by a liquid- cooled, five-cylinder Scania diesel engine.

The unit hosts the new generation Screw element in its air end combined with a Scania made diesel engine model DC09, a cooling circuit, air/oil separation and control systems, mounted on support beams and supported by rubber buffers in a spillage-free frame.

An undercarriage with fixed towbar, brakes and pintle eye is available as option.

Special attention has been given to the overall product quality, user friendliness, ease of serviceability, and economical operation to ensure best in class cost of ownership.

View and/or Download V21: Brochure / Datasheet / Engine Info Sheet

The Smart Air Xc4004 controller features the latest innovations. We believe a controller should put you in complete control, while being intuitive, and most importantly easy to use and navigate.

Smart controls also protect your investment: improve your efficiency while decreasing the operating costs of your equipment through advanced insights.

Advanced features:

No surprises:

Pressure gauge, running hours, fuel levels are always in plain sight, without toggling. Clear warning and alarm codes will clearly notify you in case of problems.

The controller will tell you when maintenance is due. If something goes wrong, alarms will notify you audibly and visually. And if something goes critically wrong, the controller will shut down the compressor and protect your investment.

| Model | V21 | |

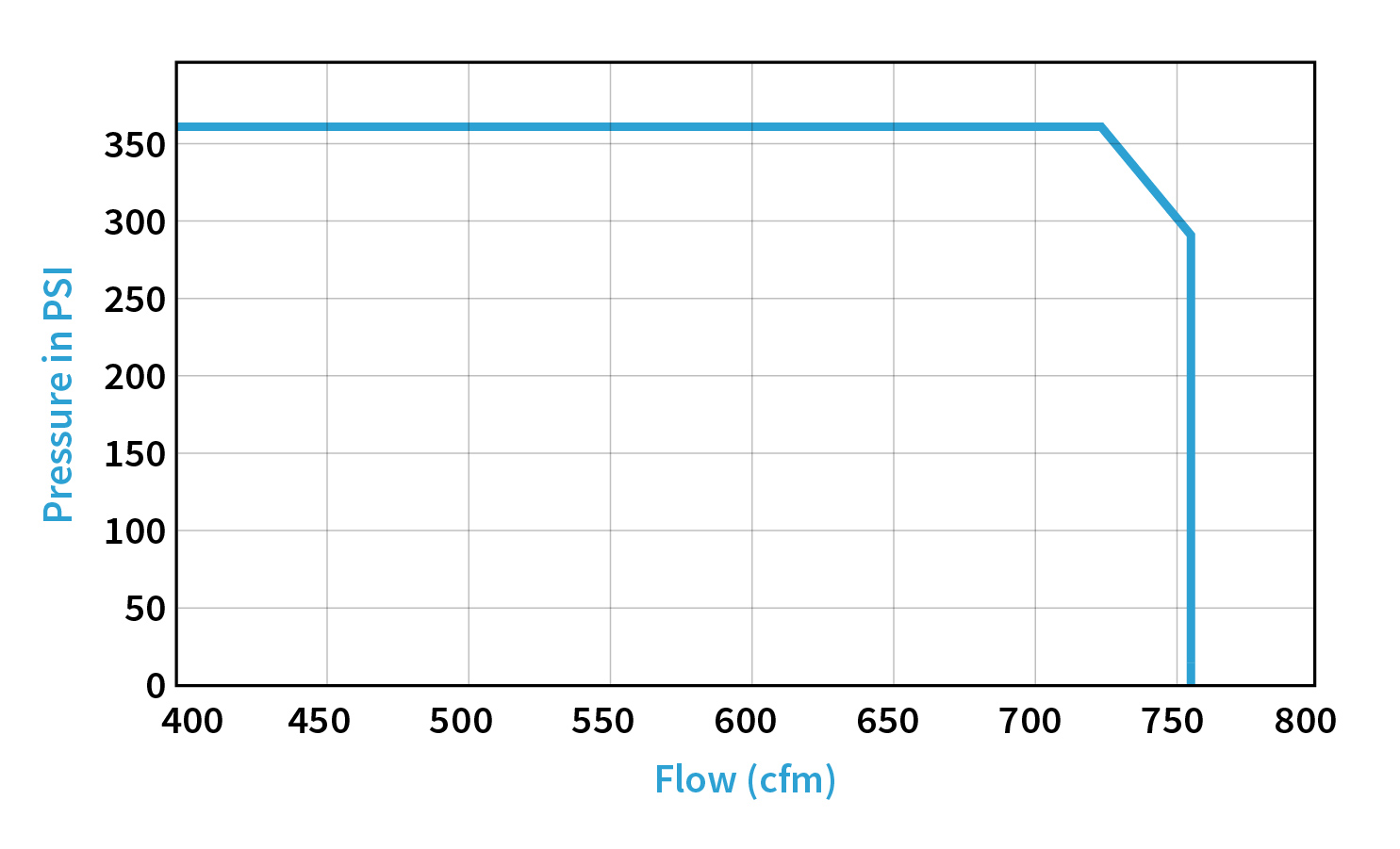

| Nominal flow at max working pressure | cfm | 758 - 725 |

| Normal effective working pressure range | psi | 232 - 362 |

| Flow in Dynamic flow boost | cfm | - |

| AirXpert 2.0 | Yes | Yes |

| XPR | - | 218 PSI |

| Fuel consumption at 100% | g/h | 13 |

| Engine make | Scania DC09 | |

| Engine power | HP | 311 |

| Emission compliance | T4F | T4F |

| DEF tank capacity | US Gal | 18.5 |

| Dimensions trailer mounted (L x W x H) | inches | 157.5 x 82.7 x 86.6 |

| Fuel tank capacity | GAL | 158.5 |

| Weight (trailer mounted) | lb | 14400 |

HDD is a trenchless technology that use surface-launched equipment to drill underground horizontally and install pipes, conduits, and cables. This process can be air-driven and are used in numerous industries, such as utilities and telecommunications, at sites in dense, urban areas and/or where traditional vertical excavations are too dangerous (e.g., under bodies of water).

Compressors in the DrillAir line can power large-diameter and/or long-run HDD processes with high throughput. The power of these units maximizes the efficiency of drilling operations, lowering project overhead and decreasing downtime.

The DrillAir range provides one of the highest air volumes at one of the highest air pressures available in the portable compressor industry. This also makes these new compressors one of the most energy efficient by having a very low specific fuel consumption for the air delivered.

Dynamic Flow Boost ® increases flow from 34.8 to 39m³/min (650l/s) when flushing and during drill stem refill. It means faster flushing, faster stem refill and a shorter time to finish a well.

High penetration rate with 35 bar pressure and 34.8m³/min (580l/s) flow means more meters drilled every day.

The units were tested both in lab and field conditions to ensure optimal performance. It’s designed to withstand the toughest working conditions. The updated HardHat canopy is our toughest, most aesthetically pleasing canopy to date. It’s corrosion free and needs no painting or dent repair.

Whether in quarries or underground applications, we have a wide range of compressors with high flow and pressure ranges. Specially for underground applications: minimize ventilation costs by selecting one of our electric driven mobile compressors.;