The next generation of compressed air filters

Because air filtration is a crucial part of compressed air systems, Atlas Copco has put together a dedicated team tasked with developing cutting-edge filtration solutions. Our scientists and engineers are closely working with universities and filter material suppliers to ensure that you get the best products on the market. In addition, all of our air filters are subjected to rigorous internal and external testing, certification and quality control.

A good filter cleans a compressed air stream to the point where it is pure enough to meet quality requirements. A great filter also cleans the air (cost) efficiently. An Atlas Copco filter does much more than that.

Meet the new generation of Atlas Copco air filters

By protecting your compressed air system from a wide range of contaminants, they increase the service life of your downstream equipment and safeguard the quality of your end products.

But that’s only the beginning. Thanks to a range of innovative features developed by our dedicated filtration team, the new generation of Atlas Copco filters offer a range of unprecedented benefits that save you money and keep your operation running.

Why do you need a filter?

Filters play a crucial role in the protection of compressed air systems. However, their importance is often overlooked … and that can be a very costly mistake.

Companies that neglect air filtration jeopardize their air-powered equipment and end products, increase operating expenses and may fail to meet air purity standards.

There are different filters for different contaminants and air purity classes. You should know which one is right for you to ensure that your air is as clean as it needs to be.

Dry dust

Micro organism

Oil aerosol

Wet dust

Oil vapor

Water drops

Atlas Copco offers a wide range of filters – each with specific benefits that allow you to optimally treat your air stream and protect your air system. We will also help you select the right one by providing you with the right tools and expert advice.

You can find out more about all the different filters on the overview page.

Innovative features that give you an edge

Atlas Copco’s latest generation of filters comes with a series of special features that will help lower your operating and energy costs, reduce maintenance times and make your processes run more smoothly.

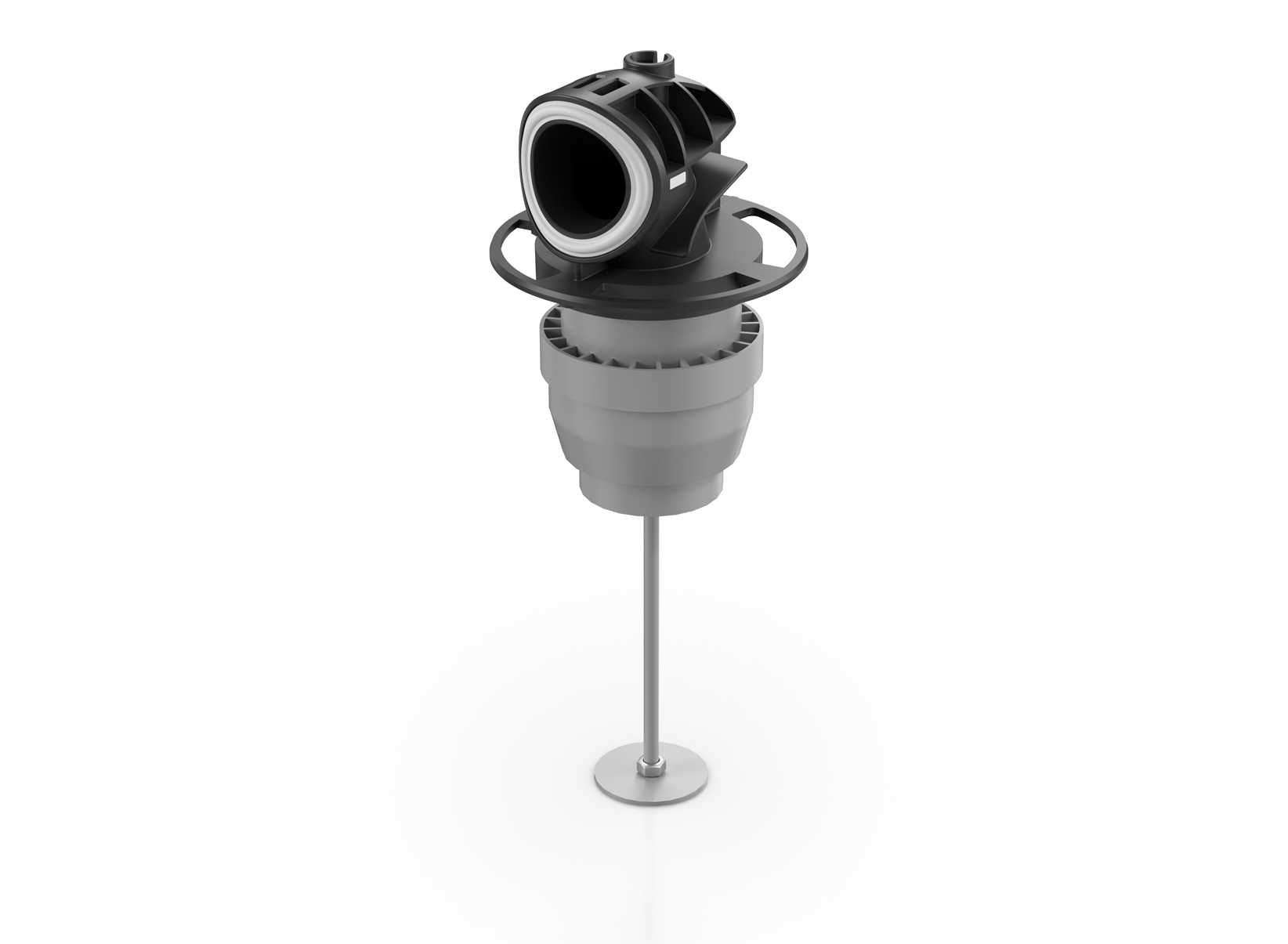

inPASS™ bypass

Until now, companies were either forced to shut down their air flow to perform maintenance of install an expensive external piping bypass.

Atlas Copco is making these suboptimal options a thing of the past with its revolutionary inPass™ bypass technology. It allows you to service your filter without disrupting the air flow.

Service indicator

To ensure constant air quality, a service indicator allows for an easy check of the filter’s running hours, differential pressure, and the maintenance status. It can even send a remote alert.

The ideal filtration technology

To ensure that your system is optimally protected, our filters use different filtration technologies – each designed to take on a distinct threat to your airstream. They include:

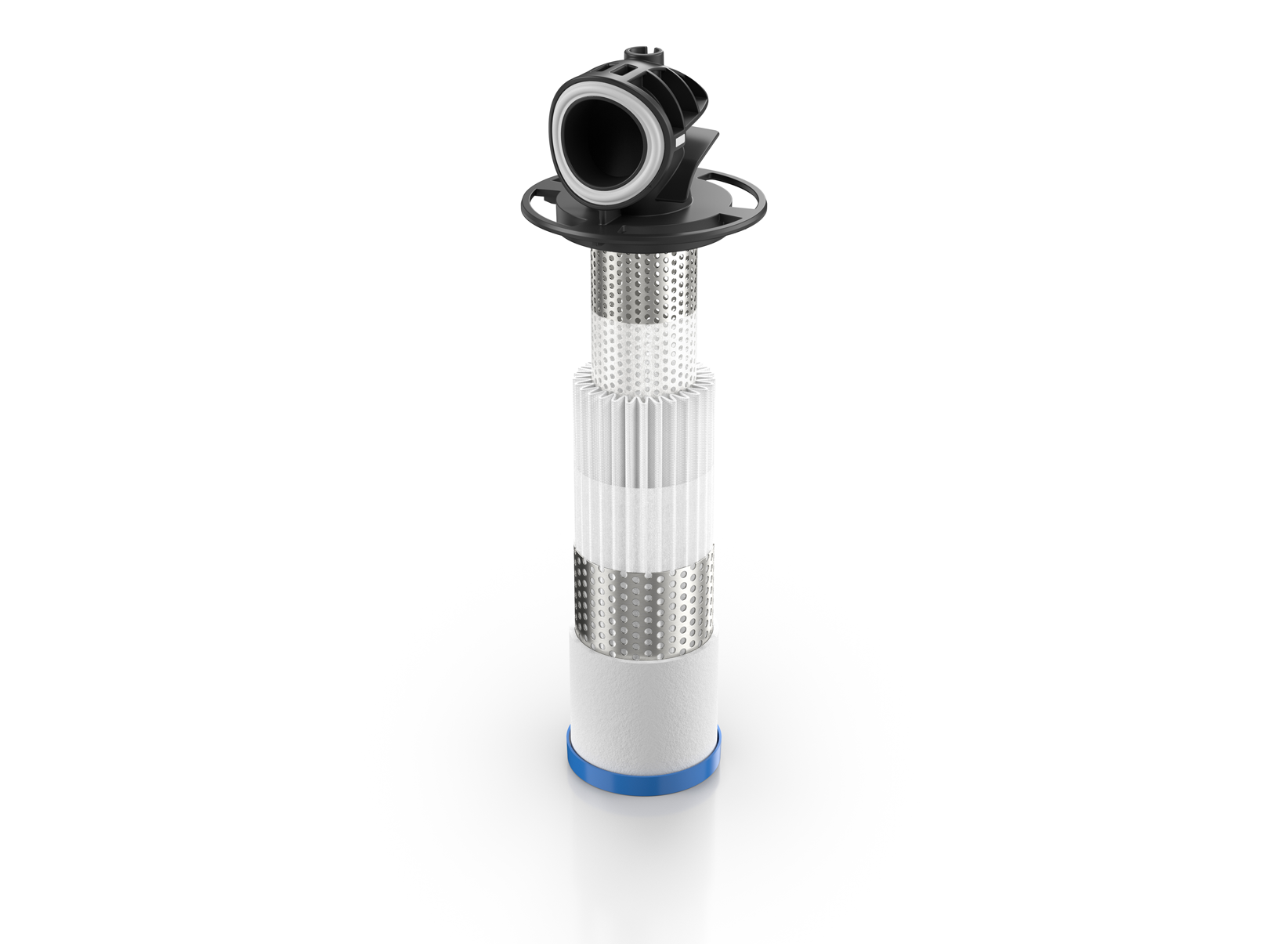

Wrapped media for wet particles

Wrapped media are known for their durability in wet and oil-contaminated environments. Our patented Nautilus technology combines multiple wrapped layers to offer constant air quality at the lowest pressure drop, even in the harshest working conditions.

Pleated media for solid particles

Pleating is the optimal technology for capturing dry particulates in compressed air. Pleated media have a large surface area and therefore ensure a longer filter service lifetime and lower pressure drop.

Macro-structured activated carbon

Macro-structured activated carbon has a larger surface compared to the typical carbon filter media, giving it a superior adsorption capacity and a steady performance over a longer time.

Cyclone for water

The use of centrifugal forces secures a proper separation of liquid water droplets in the air flow.

To find out more about our filter media and filtration innovations, check out this video.

A state-of-the-art filter range

Atlas Copco offers a complete filter range. Each model is designed to counteract a specific contaminant or for use in specialty applications.

Flanged design

Threaded design

Tower design

- Compressed air filters 5.3 MB, PDF